This website uses cookies for a better browsing experience.

If you agree to the use of cookies, please click the "Agree" button.

Please refer to the Privacy Policy regarding the use of cookies on this site.

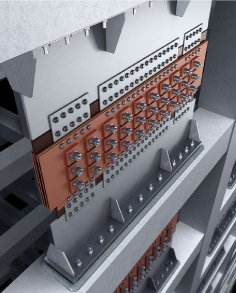

A wall-type friction damper with a low cost and excellent durability due to a simple structure

Features

- Fatigue life is not a concern, so the product is able to withstand repeated actuation and does not need to be replaced.

- Vibration dampers are effective at damping a wide range of vibrations from small tremors to major earthquakes.

- There is very little difference between static and dynamic friction, and friction materials that do not cause friction noise or vibrations (stick-slip) are used.

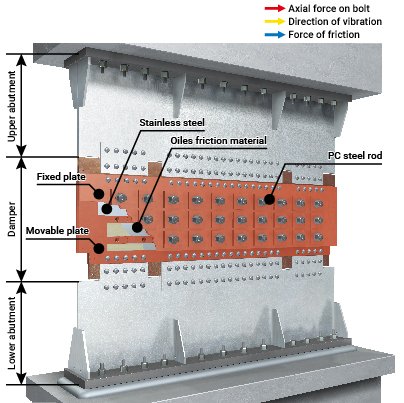

Structure and action

Structure

A WFD is a damping device that uses the frictional resistance of friction materials. An Oiles friction material and adjoining material (stainless steel) are installed between a fixed upper plate and a movable lower plate.

These are tightened with PC steel rods to transmit axial force to the friction material. Relative movement of the fixed and movable plates generates frictional force on the friction surface, producing frictional resistance.

Action

The WFD converts the deformation of a building between stories due to earthquakes and wind into relative motion of the fixed and movable plates on either side of the friction material, and it absorbs vibration energy through the frictional resistance generated in the process.

Oiles friction material

- A resin-based friction material is used. The surface is dense at the molecular level, making the material slippery due to friction.

- It can be used without lubrication and has excellent chemical and heat resistance.

Test results

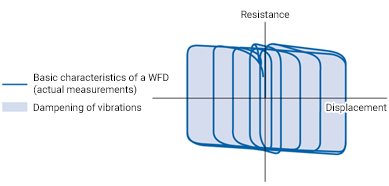

The graph shows the relationship between resistance and displacement when the WFD is subjected to small to large amplitudes, demonstrating its consistent performance.