This website uses cookies for a better browsing experience.

If you agree to the use of cookies, please click the "Agree" button.

Please refer to the Privacy Policy regarding the use of cookies on this site.

Estimation of the wear amount

Even now, there is no established method for determining the wear amount on bearings based on theoretical values. In actual design, empirical or experimental methods are considered important, such as identifying the application conditions to the extent possible and making determinations based on the results obtained from use in actual devices, bench tests, and sliding tests with conditions that are similar to the application conditions.

Formula for calculating the estimated wear amount

Typically, the volume of wear Vol is proportional to the load F and sliding distance L as shown in equation (1).

Vol=k∙F∙L・・・(1)

| Vol | Volume of wear (mm3) |

|---|---|

| k | Specific volume of wear [mm3/(N-m)] obtained from bench tests, sliding tests, etc. |

| F | Load (N) |

| L | Sliding distance (m) |

In the design of plain bearings, the wear amount (depth) is typically considered. The contact pressure P (N/mm2), sliding velocity V (m/s), and PV (N/mm2-m/s) are important parameters that determine frictional characteristics. They are often calculated as design values, so equation (2), which converts equation (1) for P (N/mm2), V (m/s), and running time T1 (hr), is used as the equation to calculate the estimated wear amount. The units for specific wear amount K are mm/(N/mm2-m/s-hr). The table below shows the approximate specific wear amount K depending on lubrication conditions.

W1=K∙P∙V∙T1・・・(2)

| W1 | Estimated wear amount (mm) |

|---|---|

| K | Specific wear amount [mm/(N/mm2-m/s-hr)] |

| P | Contact pressure (N/mm2) |

| V | Sliding velocity (m/s) |

| T1 | Running time (hr) |

Table Approximate specific wear amount K of Oiles bearings under different lubrication conditions

| Lubrication conditions | Specific wear amount K [mm/(N/mm2-m/s-hr)] |

|---|---|

| Dry |

|

| Periodic lubrication |

|

| Oil lubrication |

|

The specific wear amount K

In addition to contact pressure, velocity, and running time, the wear amount is affected by various factors such as the form of motion, hardness of the mating material, surface roughness, clearance, heat of friction, environmental temperature, ambient environment, lubrication conditions, and entry of foreign matter. Conducting bench and sliding tests in which these factors are matched as closely as possible to the conditions of the actual device yields a highly accurate specific wear amount K.

We have accumulated sliding test data under all conditions for many years, so we can provide the appropriate specific wear amount K based on the design information for your device. If you request, we can also perform a new sliding test and provide a specific wear amount K.

Formula for calculating the estimated service life

Equation (3) is used to determine the estimated service life. The allowable wear amount W2 is determined from the limit at which functioning of the device can be maintained, taking into consideration shaft misalignment due to bearing wear and interference between the shaft and other adjoining and surrounding parts. When a two-layer bearing consisting of a sliding layer and a backing layer is used, the thickness of the sliding layer is the allowable wear amount W2.

T2=W2/(K∙P∙V)・・・(3)

| T2 | Estimated service life (hr) |

|---|---|

| W2 | Allowable wear amount (mm) |

| K | Specific wear amount [mm/(N/mm²-m/s-hr)] |

| P | Contact pressure (N/mm2) |

| V | Sliding velocity (m/s) |

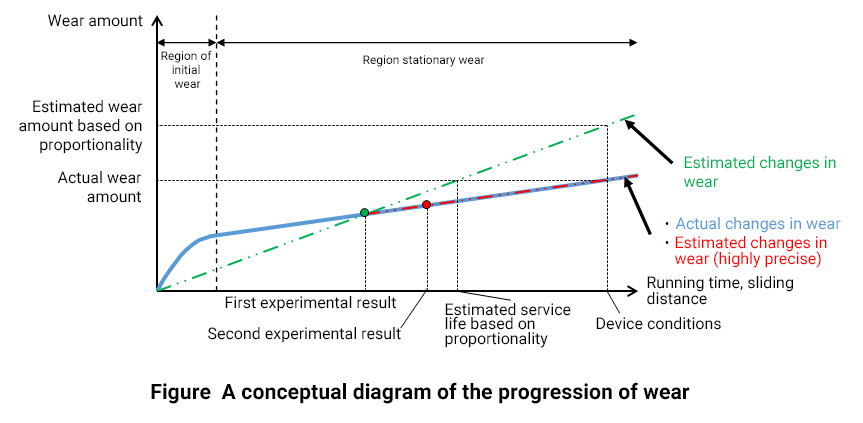

Actual and estimated changes in wear

As shown in the figure below, the actual wear of a plain bearing transitions from the region of initial wear, where wear progresses quickly, to the stationary wear, where wear progresses more slowly. The running time in bench and sliding tests is often shorter than that with an actual device. In such a case, the estimated wear amount is calculated to be larger than the actual wear amount. For the same reason, the estimated service life until the allowable wear amount is reached is calculated to be shorter than the service life of the actual device. This is something to bear in mind.

In the stationary wear in a sliding test, the wear amount is measured at two points, and highly accurate estimation can be done using the specific wear amount calculated based on the increase in the wear amount between the two points and the running time.