Installation

Installation (press-fitting)

Install (press-fit) using hydraulic pressure, pneumatic pressure, or a vise.

- Press-fitting with force, such as hammering, will result in bearing damage or a change in its bore.

When installing, use the recommended tolerance (H7) for the dimensions of the housing bore as shown in the catalog.

- #500SP1 SL1 spherical bearing (SPS): K7 (general use), N7 (high loads)

#2000 high-precision bearings (CLB and CLF): H6

When replacing a bearing in a blind hole, the design of the surroundings must take removal into consideration.

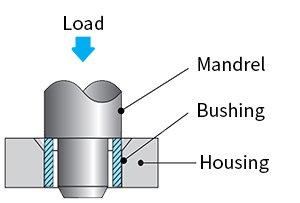

Press-fitting jig

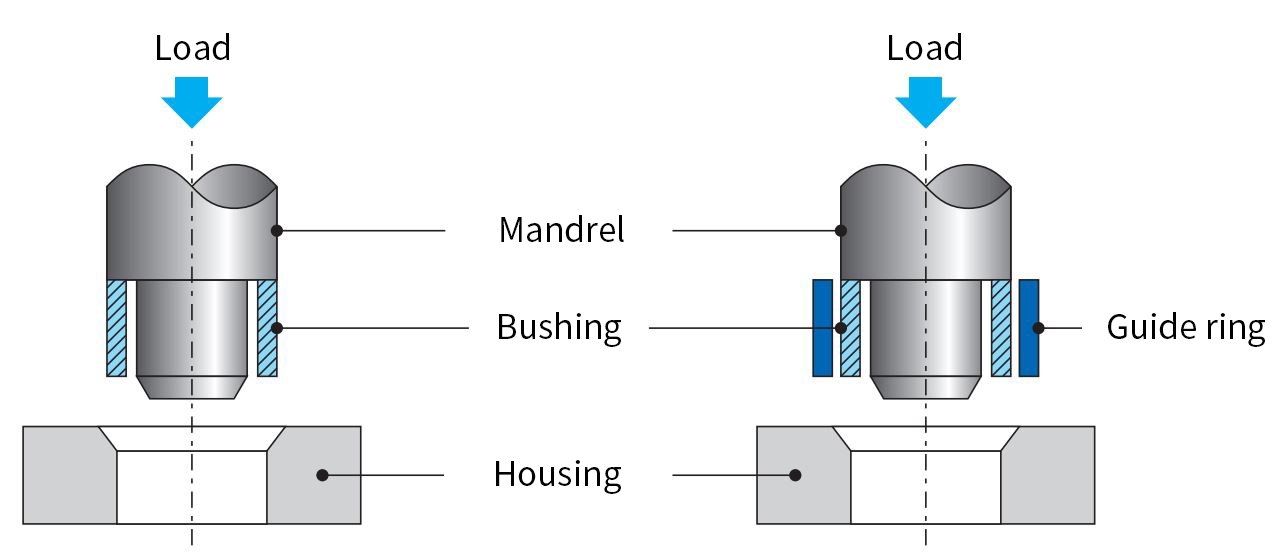

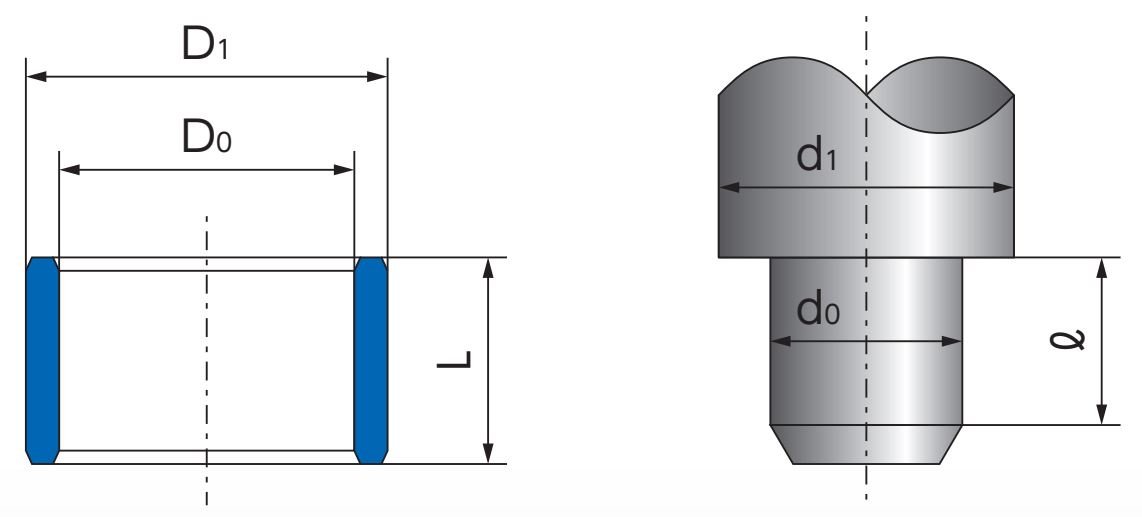

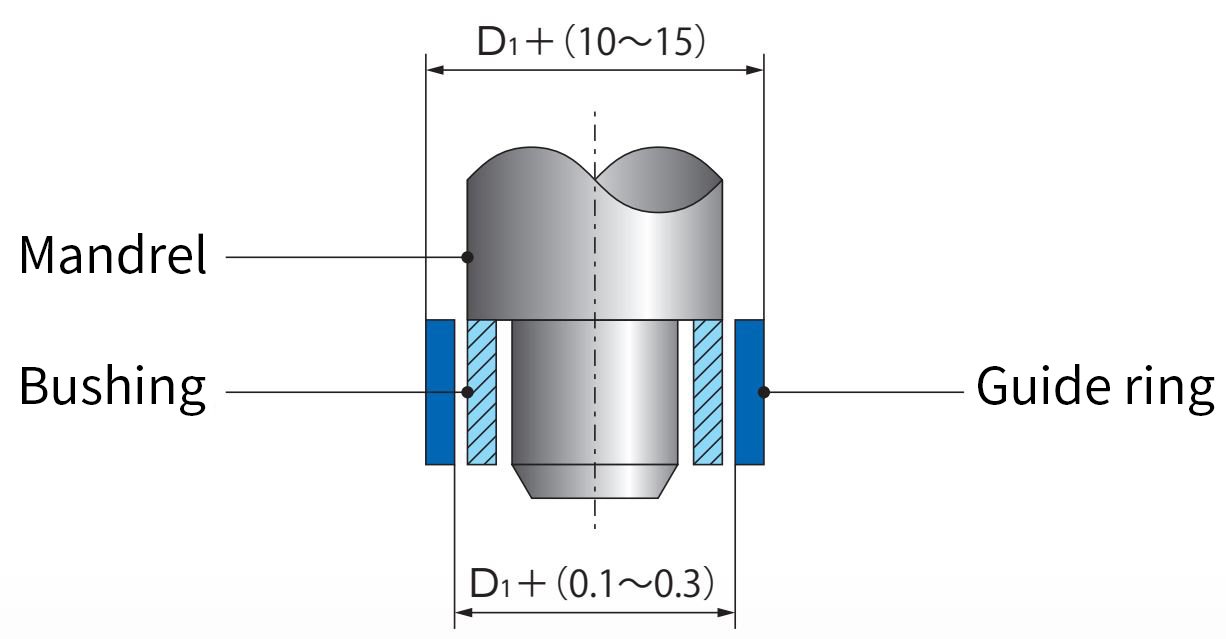

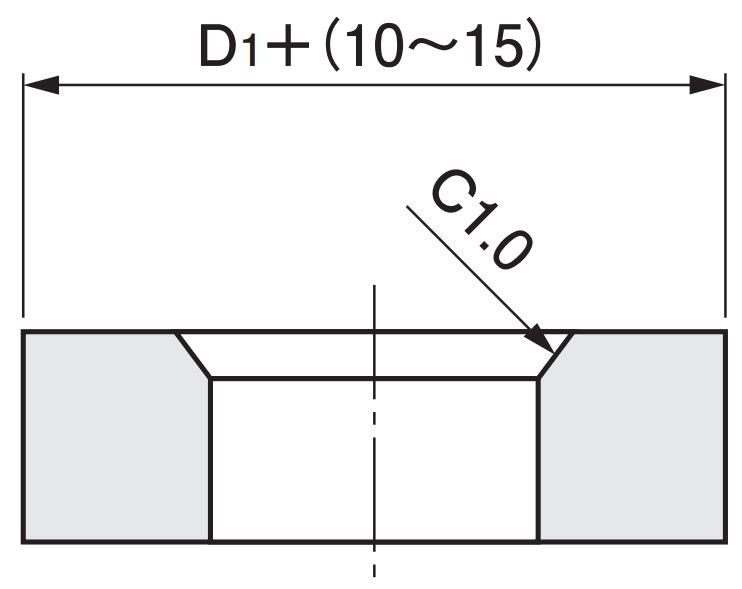

In general, use a mandrel to insert the bushing in the insertion site in the housing as shown in Figure 1.

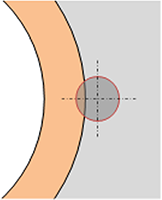

The use of a guide ring, as shown in Figure 2, facilitates press-fitting.

The use of a guide ring is effective at ensuring the roundness and centering of the bore after press-fitting and in preventing damage to the bushing during press-fitting.

When using a screw on a metallic bearing to prevent loosening or turning

A screw to prevent loosening and turning must be installed in a position away from load points. After the bearing is set in the housing, a locking screw with a diameter equivalent to the thickness of the bearing wall should be machined at a position towards the housing by about 20 to 30% of the screw diameter as shown in Figure 5.

An end mill should be used when machining holes.

After removing the screw, the bushing can easily be removed using a mandrel in the same manner as during press-fitting.